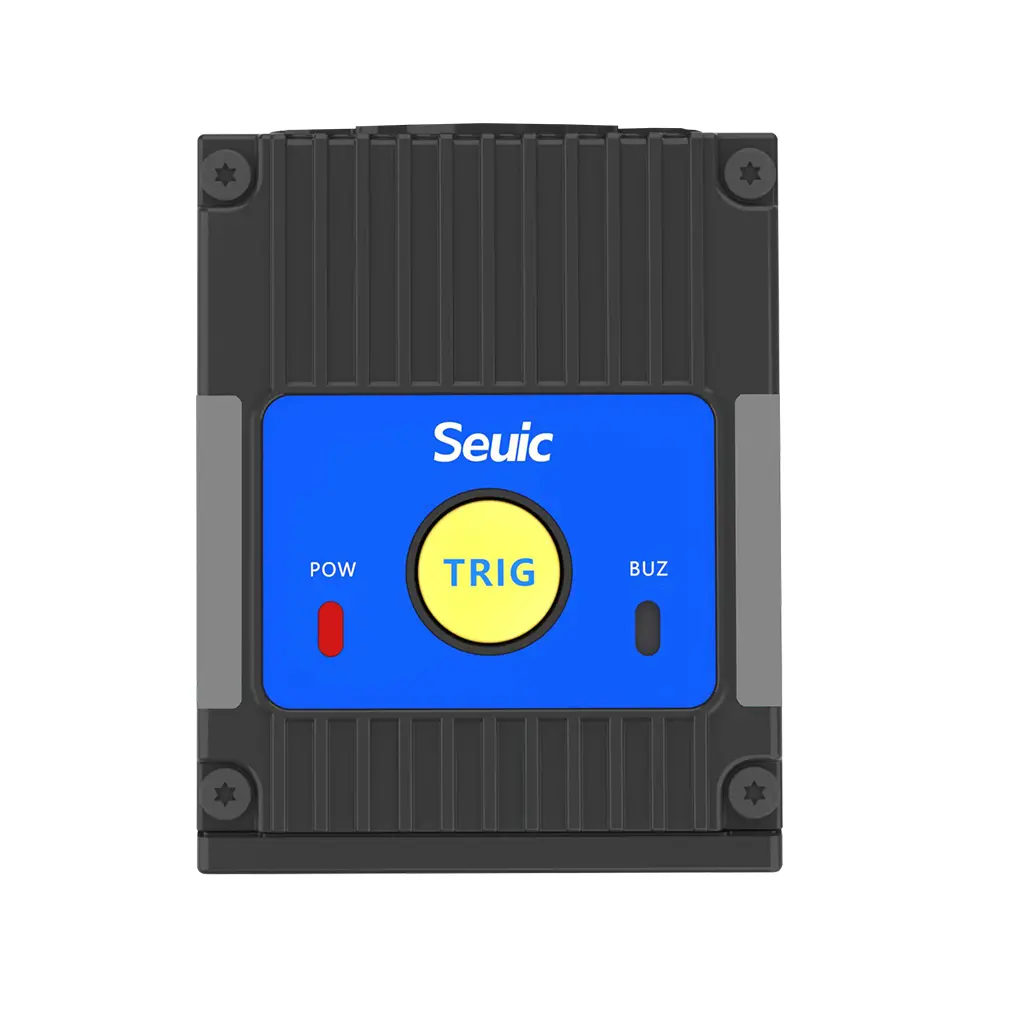

SEUIC X3G — fixed 1D/2D barcode scanner (stationary)

SEUIC X3G is a fixed 1D/2D barcode scanner for inline reading on the conveyor. Fixed mounting, built-in backlight , IO triggers for PLC and PoE Ethernet options ( upon configuration ) ensure stable decoding without operator intervention.

- Estimated delivery: up to 4 business days

- Free shipping and returns: дfor all orders over $200

SEUIC X3G — fixed barcode scanner

SEUIC X3G is a fixed (stationary) 1D/2D barcode scanner for inline reading on conveyor lines and production areas. The device automatically decodes codes on boxes, trays and parts without an operator , keeping a constant data flow in real time.

Why businesses choose X3G

-

Stable decoding at line speed. The imager reads 1D/2D (including QR/DataMatrix ) on film, glossy and at an angle.

-

Integration into the production cycle. IO triggers / PLC integration synchronizes the frame with the sensor; PoE Ethernet ( by configuration ) simplifies installation and power supply.

-

Built-in backlight. Forms a uniform scene and stabilizes inline barcode reading without external lamps (in typical tasks).

-

Multi-scanner schemes. Multiple X3Gs cover side faces and unstable orientation — full field of view coverage.

-

Compact form factor. Convenient stationary barcode scanner for tunnels, sorting units and protective covers.

Where X3G gives the most

-

Warehouses/3PL: conveyor control of selection, sorting, reconciliation upon shipment.

-

E-commerce/distribution: selection confirmation, routing, kit verification.

-

Production: traceability of components/components, labeling inspection, label-product linkage.

-

Reception/Returns: Fast inline reading of box flows without manual scanning.

How it works on the line (briefly)

-

Sensor/PLC provides IO trigger → X3G captures frame.

-

The algorithm decodes 1D/2D and returns a “success/failure” event.

-

Data enters your system via network interface/PoE ( depending on configuration ); event-driven sorting/alarming.

Why SEUIC X3G

-

Industrial level of stability in variable lighting.

-

PoE + IO/PLC = quick launch into production cycle ( by configuration ).

-

Multi-scan scalability for complex orientations and wide areas.

FAQ

Does the X3G read at an angle or from the side faces?

Yes; for unstable orientation, a multi-scanner scheme with multiple X3Gs is used.

Is external lighting needed?

In typical tasks, the built-in is sufficient ; for complex surfaces, we will select external light/filters.

How to integrate with tape and PLC?

Through IO triggers and network interfaces; success/failure events are supported to control sorting.

What codes are supported?

Standard 1D/2D (please refer to your specifications table for the exact list).

| Technical specifications | |

|---|---|

| Image sensor | 1280*800 COMS with global shutter |

| Light | High-intensity red LED |

| Aiming | Red linear collimator |

| Number of frames | Maximum 60 frames/sec |

| Code support | 1D: all standard 1D barcodes 2D: DataMatrix (ECC200), QR code, Micro QR, PDF417, MicroPDF417, Aztec, etc. |

| Rotation | Omnidirectional reading |

| Precision | 1D: 3.3mil 2D: 5.0mil |

| Standard range for typical characters | HD SR : 3.3mil Code 39: 40-80 mm 10mil Code 39: 50-150 mm 10mil Datamatrix: 30-130 mm ENA-13 100%: 30-165 mm |

| SR : 10mil Code 39: 50-200 mm 10mil Datamatrix: 35-250 mm ENA-13 100%: 30-300 mm |

|

| Sight | 46° horizontal, 29° vertical |

| Operation mode | Manual, presentation, continuous, command via serial port |

| Print contrast | ≥30% |

| Communication interface | USB, RS-232 |

| Dimensions | 40mm x 50.3mm x 23mm |

| Weight | About 34g |

| Operating temperature | 0℃ to 50℃ |

| Storage temperature | -20℃ to 70℃ |

| Humidity | 5% to 95% RH, non-condensing |

| Protection class | IP54 |

| Housing material | Aluminum alloy + ABS |

| Protection class | IP54 |

|---|

Reviews

There are no reviews yet.